Work with us

Aurobay powertrain experts support OEMs and tier 1 suppliers in developing and manufacturing innovative, sustainable, highly efficient powertrains

Case studies

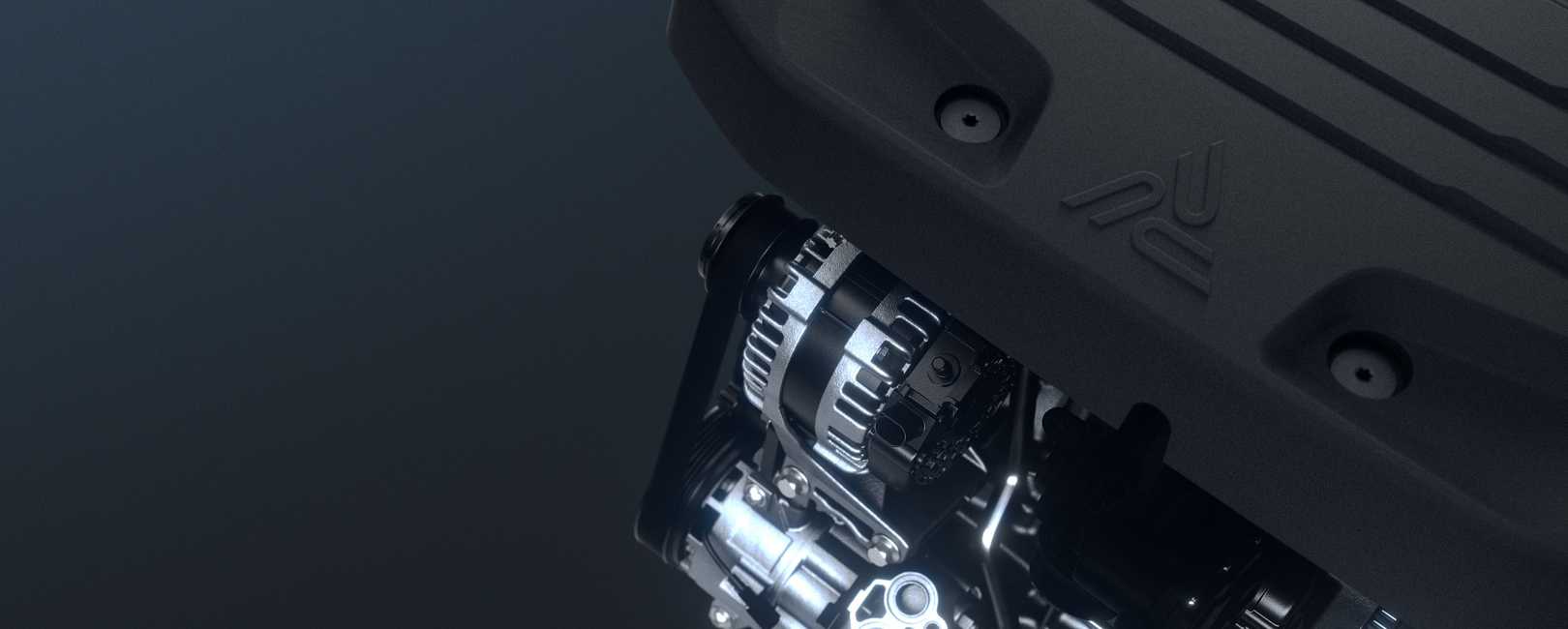

Next-generation entry level 4 cylinder gasoline engine with astonishing fuel efficiency

Aurobay’s newest engine, 200hp 2-0l miller engine designed and manufactured in-house, meets the toughest fuel-efficiency and emissions targets, with great performance.

Client Volvo Cars

Year 2021

Read more1/3

Want to know more?

Contact us →

Designed with electrification in mind, our compact hybrid-ready engines are clean and efficient.